Diamond cup grinding wheels are manufactured by specialized factories that focus on producing abrasive tools for grinding and surface preparation applications. These factories typically use advanced production techniques to bond synthetic diamonds with materials like steel or aluminum to create durable and high-performance grinding wheels.

They often produce various types of diamond cup wheels tailored to specific applications, such as concrete, masonry, stone, and metalwork, with configurations like single row, double row, turbo, and segmented cups.

Here are a few things commonly emphasized by reputable factories that produce diamond cup grinding wheels:

1. Material Quality: High-grade industrial diamonds are used to ensure longevity and effective grinding. Factories carefully source diamonds and test materials to meet quality standards.

2. Bonding Technology: The bonding method is crucial to a wheel’s performance. Factories may use vacuum brazing, sintering, or electroplating to attach diamonds to the wheel body, depending on the desired application and durability.

3. Precision Engineering: Factories design the cup wheels with precision to ensure balance, minimize vibration, and promote a smoother grinding experience.

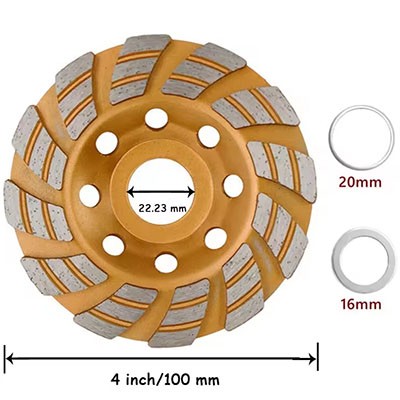

4. Customization Options: Some factories offer customization to meet specific industrial needs, such as particular grit sizes, bonding hardness, and wheel diameter.

5. Quality Control: Factories usually conduct extensive testing on durability, sharpness, heat resistance, and performance under various conditions.

Jiangsu Yabang Tools Co., Ltd.diamond cup grinding wheels factory

Contact:Kevin

Phone:+86 18362001166

E-mail:yabon_kevin@163.com

Add:No. 253, Dongfang Industrial Park, Houxiang, Danbei Town, Danyang City, Jiangsu Province, China